Waterjet Jobs

We strive to offer design and build opportunities at no cost on almost all of our equipment and tools. However, for the sustainability of the MakerSpace, we charge for the material used on the Omax Waterjet. Below are steps to calculate the cost of a waterjet job. You will need to pay that amount through the ECST Fiscal Office ET A-241 from your IRA (student teams/orgs), department for courses, or research funds for researchers.

Please come to ET B-111 and discuss with our staff to have your parts completed on the water jet.

Calculating the cost for a waterjet job:

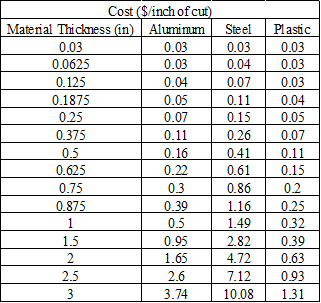

You will calculate a quote using the table below.

First, you need to find the length of your cut. There are two methods we suggest:

a. In Solidworks, click on the face of the solid. Under the evaluate tab, if you hit measure, it will give you the perimeter of the surface. Make sure to use INCHES.

b. You can open a .DXF file in Solidworks as a "Sketch" and then select all the lines and under the evaluate tab, hit measure. Make sure to use INCHES.

Using the table below, multiply the cost per inch by the length of your cut in inches. That is the amount you will pay to the ECST Fiscal Office.

Table 1. Waterjet Cost per inch of cut based on material type and material thickness

Submission instructions for after meeting with staff

Uploading waterjet jobs:

Scan the QR Code below, or use the link: https://forms.gle/8gYcKWdLa9NvCC4m7

You will need to have a DXF file of your part to upload in the google form and to calculate the length of cut. Please make sure your .dxf file is in INCHES. The Omax Waterjet software only reads files in INCHES.