Hydrogen Research and Fueling Facility

Built in 2011, Cal State LA Hydrogen Research and Fueling Facility (HRFF) is the largest self-producing station among universities in the world. The HRFF is actively engaged in research, demonstration projects, and community outreach. It can produce up to 60 kg/day—sufficient to fuel up to 20 vehicles per day. The station utilizes a hydrogenic electrolyzer, first- and second-stage compressors capable of fast-filling at 350 and 700 bar, 60 kg of hydrogen storage, water purification, and a cooling system at -20°C. Just recently, the station has switched to 100% renewable solar power generated on campus − the only academic institution in the world to do so. CSULA has been a university member of the California Fuel Cell Partnership since 2012. The HRFF has also participated in multi-year data collection, hydrogen safety workshops, and equipment deployment in collaboration with the National Renewable Energy Laboratory. The initial $4,500,000 station funding partners included the California Air Resources Board, the Department of Energy, AQMD, MSRC, the Automobile Club of Southern California, and the Ahmanson Foundation.

NMR Facilities

The NMR facilities houses two Bruker Avance II 400 MHz NMR Spectrometers and a Bruker Avance 600 MHz solid-state/micro-imaging NMR spectrometer. A variety of nuclei may be observed: 1H, 13C, 31P, and 19F. Variable temperature control is available, over the range of -50 to 80 degrees.

Campus 1 MW solar system facilities

The solar PV system generates 1 MW of renewable energy for EV charging and hydrogen generation, estimated to reduce Cal State LA's CO2 emissions by 596 metric tons (about 4% of the universities total carbon emissions).

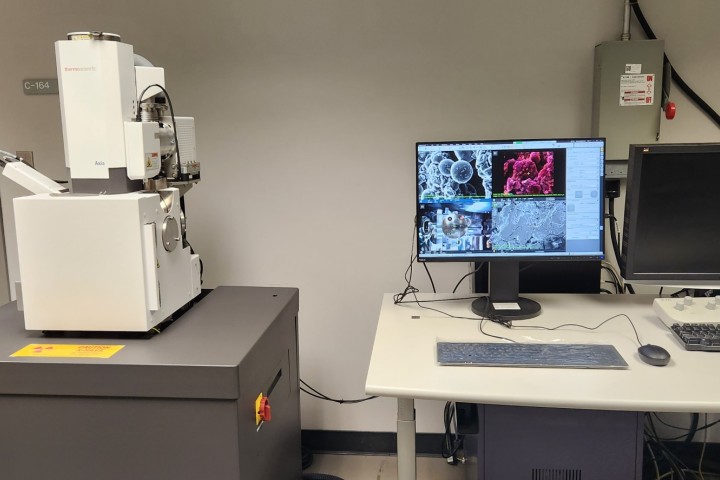

Materials Characterization Laboratroy

The Materials Characterization Laboratory (MCL) is located in the College of Engineering, Computer Science, and Technology (ECST). The MCL is equipped with various characterization equipment including electron microscopes, optical microscopes, XRD, and AFM.

Equipment

- Two Bruker Avance II 400 MHz NMR Spectrometers

- Bruker Avance 600 MHz solid-state/micro-imaging NMR spectrometer

- Agilent 5977B gas chromatography-mass spectrometry detector (GC/MSD) with EI, a single quadrupole, and split to an FID

- Agilent Gas Chromatography coupled with 7000D Quadrupole MS/MS

- A NEXGEN Complete Glovebox System with inert gas purification for storing air-sensitive chemicals and catalysts

- Fluorolog-QM Fluorimeter with the lifetime measurement capability

- Electron paramagnetic resonance (EPR) spectrometer

- Applied BioSystemsa MALDI-TOF-MS

- Thermo-Fisher Fleet LCQ liquid chromatography-electrospray mass spectrometer

- Nicolet 6700 FTIR Spectrometer with NXRFT-Raman module

- Nicolet Continuum IR microscope module

- A benchtop thermal evaporator for thin-film coating (model TBB-IV, Denton Vacuum)

- Dynamic light scattering (Zetasizer) for measuring particle size distribution and surface charges

- Waters 600 HPLC System equipped with a 2996 Photodiode Array Detector

- Perkin-Elmer Elan-DRC inductively coupled plasma-mass spectrometer

- Perkin-Elmer ScanArray Gx microarray scanner for microarray fluorescence scanning

- JASCO circular dichroism spectrometer

- A scanning electron microscope (FEI) and an EDX Spectrometer

- Atomic Force Microscopy (AFM) – Bruker Dimension Icon with Scanasyst

- Optical Microscopy – Keyence VHX-7000 4K High Accuracy Digital Microscope, Amscope Inverted Metallurgical Microscope, Olympus BX51 Fluorescence Microscope, Nikon Elipse ME600 Microscope, Nikon Epiphot 300 Inverted Metallurgical Microscope

- Transmission Electron Microscopy (TEM)

- Single-Crystal X-ray Diffractometer

- 7 Tesla superconducting magnet with a variable temperature cryostat continuously varied from 2.5 to 700 K

- Quantum Design Physical Property Measurement System (PPMS) and electron paramagnetic/ferromagnetic resonances (EPR/FMR) for magnetometry measurements

- AFM/MFM operating with Quantum Design PPMS system

- Fumehoods equipped with Schlenk lines for air-sensitive reactions and common equipment for organic and materials synthesis, such as analytical balances, rotary evaporators, glassware, and hot plates (Liu, Selke, and Ba Labs)

- Micromeritics ASAP 2020 Plus Micropore Analyzer with Vapor Sorption Accessory (Liu Lab)

- A Thermo Scientific Nicolet 380 FT-IR spectrometer (Liu Lab)

- A Discovery TGA55 Thermogravimetric Analyzer (TGA) with high sensitivity (Liu Lab)

- A D2 PHASER - X-ray Powder Diffraction on a desktop for materials characterization (Liu Lab)

- Cressington 108 Auto Sputter Coater (Liu Lab)

- Newport LCS-100 Solar Simulator (Liu Lab)

- Samdri PVT-3D Critical Point Dryer for materials activation (Liu Lab)

- Three forced air ovens with precise temperature control for materials synthesis (Liu Lab)

- Two VWR 1400F Vacuum Ovens for drying materials before high vacuum activation (Liu Lab)

- Two Eppendorf Centrifuge 5430 used for materials washing and purification (Liu Lab)

- A full set of Schlenk Line in every fume hood for air-sensitive reactions (Liu Lab)

- UV-vis spectrophotometer (Shimadzu) with an integrating sphere accessory (Selke Lab)

- Nanosecond pulsed Nd:YAG laser with output at 532 and 355 nm for time-resolved near-infrared (NIR) spectroscopy (Selke Lab)

- Germanium liquid-nitrogen cooled photodiode for detection of NIR radiation with various band-pass filters and oscilloscope (Selke Lab)

- Transparent Dewer flasks for irradiation at variable temperatures and steady-state photolysis setup (Selke Lab)

- Microplate reader, environment-controlled freezer, and lyophilizer (Ba Lab)

- LECO's QuadJet SD Comprehensive Two-Dimensional Gas Chromatography (GC×GC) combined with Flame Ionization Detection (FID) (Vozka Lab)

- LECO's Benchtop Comprehensive Two-Dimensional Gas Chromatography Time-of-Flight Mass Spectrometer Pegasus® BT GCxGC-TOFMS (Vozka Lab)

- LECO's Benchtop Gas Chromatography Time-of-Flight Mass Spectrometer Pegasus® BT GC-TOFMS (Vozka Lab)

- Fuel cell training equipment, H2 ZEV equipment, and equipment associated with the Hydrogen Research and Fueling Facility (Blekhman Lab)

- Optical equipment to visualize the gaseous flow, including lenses, mirrors, a light source, and associated hardware (Medina Lab)

- Linux-based workstations and multi-CPU computers for theoretical condensed matter research (Jishi Lab)

- Tri-arc furnace with crystal puller designed to produce poly- and single-crystal intermetallic compounds (Bernal Lab)

- Crystal grower with an iridium crucible and an iridium crystal seed rod (Bernal Lab)

- High oxygen-pressure furnace, high-temperature muffle furnace, tubing vacuum furnace, single-zone tube furnace (Bernal Lab)

- Dual zones quartz tube furnace and three-channel gas control by float-meter, oxygen-isotope exchange apparatus (up to 1200 oC) (Bernal Lab)

- Microbalances (Bernal and Ba Labs)